The MECCO Blog

The permanent identification of a part for tracking purposes can be complicated depending on the part's shape. Round parts, such as pipes, flanges, and couplings, require unique marking equipment to ensure a quality mark around the diameter. The FM200 Flange/Coupling Marking System combines MECCO's industrial strength dot peen impact marking technology with a precision rotary chuck […]

To overcome today's industrial challenges, manufacturers need to work smarter by connecting the factory. They need to increase efficiency, reduce costs, and increase quality. All of these goals can be accomplished using an integrated track and trace system. Traceability systems utilize devices such as conveyors, robotics, and vision systems, which communicate directly with a PLC using […]

The Automation Fair from Rockwell Automation is taking place in Anaheim, CA on November 19th-20th. The conference is focused on showing how “The Connected Enterprise can help you achieve faster time to market, optimize your assets, lower your total cost of ownership and improve enterprise risk.” As a new Encompass Partner, MECCO will be exhibiting for the first […]

Fabtech 2014 begins in Atlanta today and runs through Thursday, November 13th. For demonstrations of traceability solutions, visit MECCO in booth #B4624, where we will be displaying laser marking equipment alongside dot peen marking equipment, providing an array of part marking options for a variety of application needs. From portable deep marking to fast, automated solutions, MECCO uses its 125 years of experience to determine […]

MECCO’s EtherMark-enabled products have been accepted into the Rockwell Automation Encompass™ Program as a referenced product. EtherMark® is the first commercially available solution for laser and dot peen marking systems to connect and communicate directly with factory floor PACs / PLCs using native EtherNet/IP™ protocol. EtherMark is ODVA compliant, meaning that it is a certified EtherNet/IP™ solution. MECCO® participates as an […]

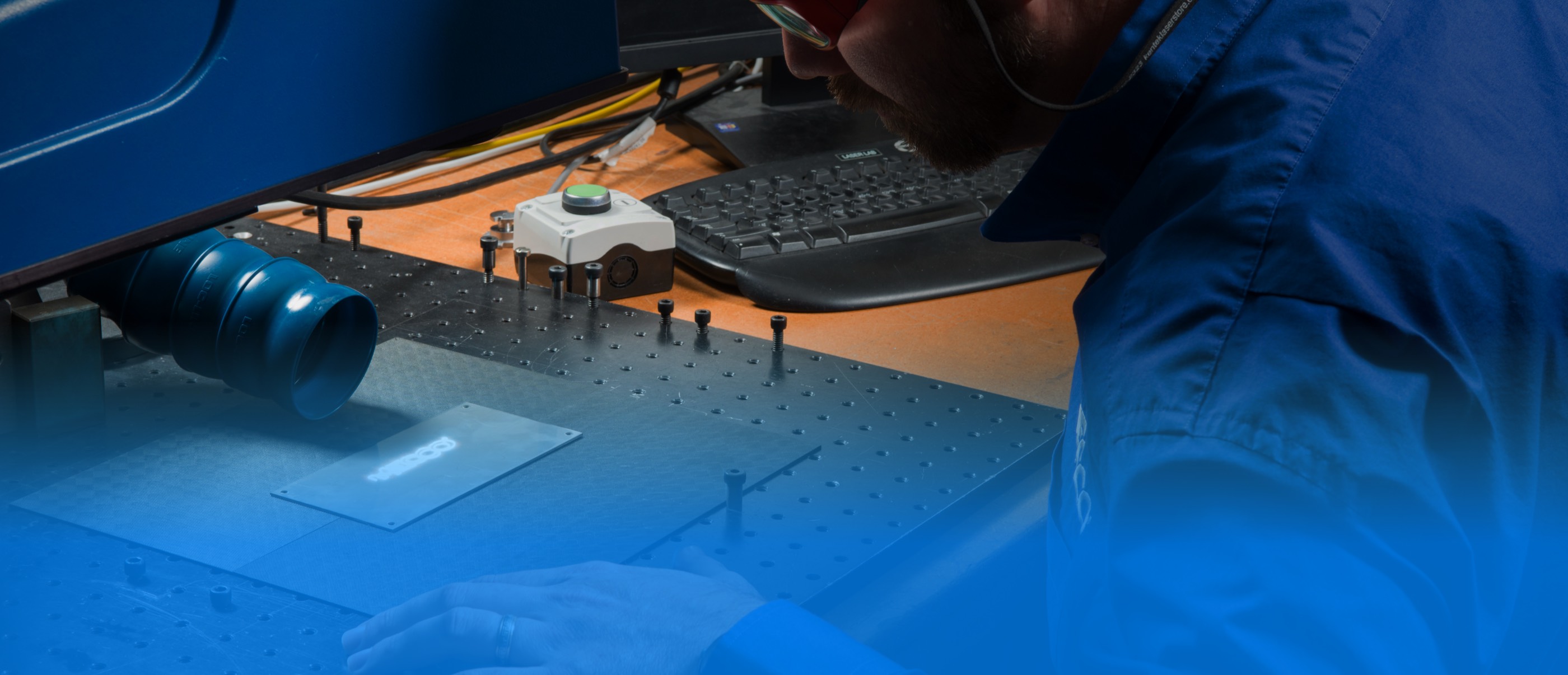

Most factory equipment is controlled through programmable logic controllers (PLCs) to automate processes in assembly lines. While devices such as conveyors, robotics, and vision systems typically communicate directly with a PLC using EtherNet/IP, historically, marking systems have used proprietary Application Programming Interfaces (API’s). Until recently, it has been a challenge for those looking to incorporate […]

In less than two weeks, IMTS 2014 will kick off at McCormick Place in Chicago, Illinois for the more than 100,000 buyers and sellers from all over the globe who attend. The International Manufacturing Technology Show is in it's 30th edition, while MECCO® Marking & Traceability celebrates its 125th year in business in booth #N-6058. New For IMTS […]

MECCO’s dot peen markers are versatile and durable, but in some environments, an impact marker can be too loud. One customer wanted to take advantage of the mark quality and speed that the COUTH product offers, but had strict requirements for the noise level and safety surrounding the marking equipment. MECCO proposed a unique configuration of their […]

How three companies have improved their processes with the new native EtherNet/IP Marking Device Integration Most factory equipment is controlled through programmable logic controllers (PLCs) to automate processes in assembly lines. While devices such as conveyors, robotic devices, and vision systems typically communicate directly with a PLC using EtherNet/IP™, historically, marking systems have not. Therefore, it has […]

This month's featured laser marking system is the MeccoMark Rotary Workstation, customized for an application that had the following goals: optimize the marking cycle by putting the maximum number of parts in at once, be able to see inside the enclosure for setting up a job file, and have easy access for maintenance. To do […]