The MECCO Blog

Mecco announces its new MeccoMark Fiber Laser with EtherNet/IP, a refined marking system focused on simplifying integration and usability. Featuring EtherMark: EtherNet/IP for Marking Devices, laser marking devices now have the ability to communicate directly with a programmable logic controller (PLC) via EtherNet/IP. Save time and money with the first technology solution that eliminates custom programming of […]

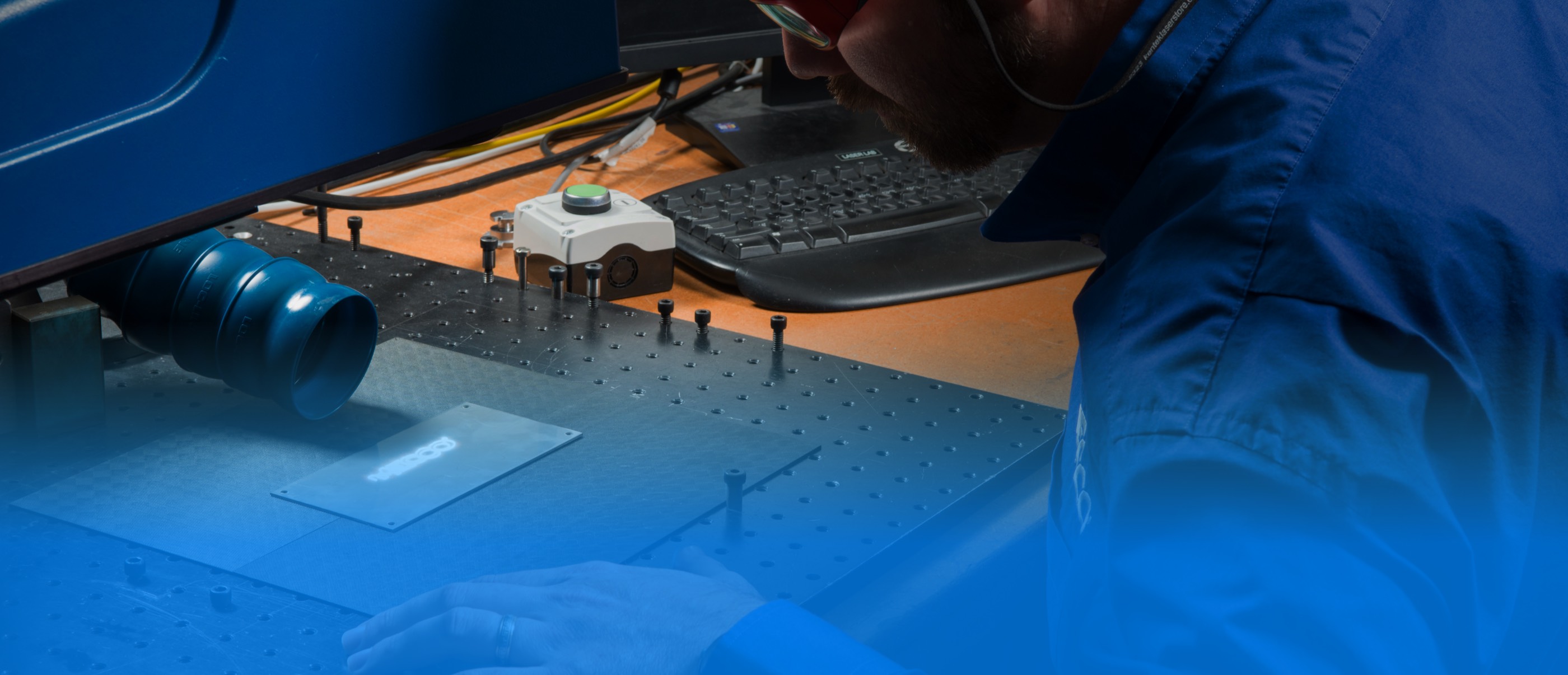

MECCO is proud to announce the release of its new MeccoMark Fiber Laser Marking System, which features patent-pending technology that facilitates integration of the marking system into factory automation networks using EtherNet/IP protocol. Mecco developed this method of integration along with embedded control technology in order to save manufacturers time and money by eliminating the need […]

Mecco has launched "Mecco® VPS": a new online product support portal that gives customers 24-7 access to training and troubleshooting videos. Building upon the world-class service that Mecco offers, this digital format for getting support provides customers with a valuable online tool that can be referenced and used for training new employees on the proper […]

Dot peen marking is a permanent, direct part marking process using a carbide pin to indent the marking surface to form continuous lines, logos and 2D Data Matrix bar codes. When considering an impact marker, it is important to weigh the advantages of each technology that the markers are capable of so that you can choose the […]

This demo video shows our dot peen marking equipment with the benchtop mounted rotary chuck. This add-on to the COUTH line of dot peen and Vibra Peen products allows for circumference marking with our standard marking heads. Take advantage of the proven reliability and speed of the COUTH dot peen markers for round part applications. […]

New in Laser Safety: Safety Seal for Laser Markers Laser marking large parts typically presents a challenge in incorporating a large enclosure, but Mecco® has revolutionized the way laser marking is accomplished on the production floor. In this video, we show a breakdown of the key features of Mecco's patented innovation, the Safety Seal for Laser Marking Systems, […]

The July 2013 issue of New North Business Matters features a profile of Mecco Marking & Traceability and the transformation that the company has undergone throughout its history. This transformation has seen a great change in technology for both the marking and the traceability of parts made by manufacturers in various industries. Below is a preview […]

If you're evaluating new part marking systems, there are more factors to consider beyond a laser marker vs. a dot peen marker. For one, what type of mark are you looking for? Laser markers are capable of creating a wide range of marks on a variety of materials, from stainless steel, to plastic and bronze. […]

Traceability is the process for locating components and their appropriate history throughout their life. Implementing a traceability system allows for tracking all WIP and reports production, verifying processes, providing complete lot traceability, and links operator and machine to part being made. Traceability Components: Do you need to implement or improve traceability for your processes? There […]

New Type Of Bar Codes Is Tool For Quality, Inventory And Warranty Control Find out how this company achieved individual parts traceability throughout the production line. The bar coding of finished products is an effective and widespread tool for managing inventory and distribution, expediting work-in-process and simplifying warranty fulfillment. What has not been practical is […]